Mining and Metals | Indonesia

Context

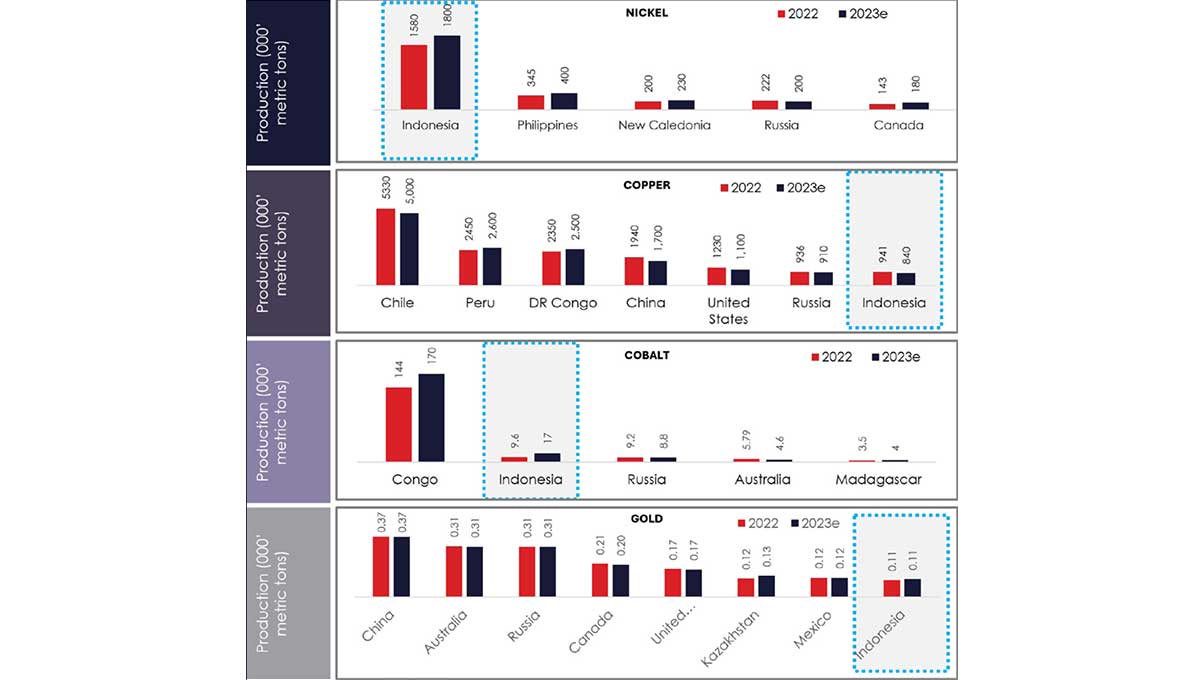

As the world’s largest nickel producer and major supplier of other critical minerals, Indonesia stands at the forefront of the global mining industry.

However, organizations need to take a strategic approach to fully capitalize on this opportunity, balancing operational efficiency and sustainability for long-term growth.

Approximately

30%

of mining and metal operations in Indonesia are currently integrated. How can organizations streamline across the value chain?

Key Takeaways

Mining and metals companies in Indonesia are uniquely positioned to capitalize on the rising demand for critical minerals. By embracing sustainability, operational excellence, and stakeholder engagement, these organizations can harness Indonesia’s rich mineral wealth to drive economic growth and environmental stewardship.

- Downstream Processing:

Indonesia’s push for mineral beneficiation presents opportunities for companies to invest in downstream processing facilities, such as smelters and refineries. This not only aligns with the government’s goals but also unlocks higher-value exports and creates employment opportunities.

- Renewable Energy Integration:

As the mining industry seeks to reduce its carbon footprint, Indonesia’s abundant renewable energy resources, including geothermal, solar, and hydropower, offer opportunities for companies to transition towards cleaner and more sustainable operations.

- Technology and Innovation:

Adopting cutting-edge technologies, such as automation, digitalization, and advanced mineral processing techniques, can enhance operational efficiency, safety, and environmental performance, positioning companies as industry leaders in sustainable mining practices.

- ESG and Stakeholder Engagement:

By implementing robust environmental, social, and governance (ESG) practices, companies can align with global standards and ensure responsible operations. Engaging local communities and stakeholders builds strong relationships and garners essential support. Additionally, investing in workforce training enhances skills and drives innovation. These efforts collectively enable companies to navigate industry complexities and secure long-term success.

Integrating mining and smelting operations enhances efficiency and promotes sustainable growth. By combining mining with downstream processing, adopting new technologies, prioritizing ESG practices, and focusing on workforce development, we can ensure regulatory compliance, safety, and sustainability.

It is critical to take a cohesive and strategic operational approach, while adopting responsible mining practices, to drive performance, reduce emissions, and enhance skillsets for long-term growth.

Addressing these issues is essential for successful integration and sustainable growth.

- Complex Commissioning Process

Smelting operations require strict conditions, high-quality raw materials, and precise molten metal management. The use of imported technology necessitates a skilled workforce, continuous training, and reliable energy management to ensure successful commissioning.

- Broader Operational Risk Profile

Adding smelting operations introduces complex process risks to existing mining risks, such as furnace ruptures, which can cause catastrophic damage and operational disruptions. Managing these risks requires strict technical competencies, strict safety protocols, risk awareness and vigilant oversight.

- Limited Supply of Skilled Labor

Smelting operations demand a highly skilled workforce, but Indonesia faces a labor shortage with less than half the working-age population having upper secondary education. Rapid industry growth necessitates effective strategies for upskilling and retaining talent.

- Integrating Smelting Operations with Mining

Careful management of ore quality and specifications, coupled with a robust Sales and Operations Planning (S&OP) process is essential to coordinate resources and production. Different operational cultures add complexity, requiring strategic coordination and cultural alignment.

- Greater Sustainability Impact

Smelting operations are energy- intensive and result in higher emissions, demanding comprehensive energy management and monitoring. Companies must adopt rigorous sustainability measures to comply with environmental regulations and minimize their impact.

Without a cohesive plan that aligns mining and smelting activities, companies may struggle with resource allocation, production scheduling, and maintaining the quality of blended ore needed for smelting.

The silos and the lack of integration across mining and smelting operations can result in lower productivity, higher operational costs, and increased risk of conflicts between departments.

Long-term growth hinges on a multifaceted strategy that prioritizes risk management, operational excellence, and workforce development.

Proactive Risk Management:

From regulatory changes to environmental considerations, it is critical to anticipate and mitigate risks with proactive risk management for seamless operational continuity.

Infrastructure Investment and Organizational Support

Investing in modern infrastructure and technology helps companies to adapt to market demands at scale and speed.

Operational Excellence and Quality Control

Optimized processes and stringent quality control measures will enhance productivity and strengthen competitive positioning.

Workforce Development and Knowledge Transfer

Continuous learning fosters innovation and adaptability, equipping employees to contribute to long-term growth.

Cultural Integration and Engagement

It is key to bring together a diverse workforce, fostering a vibrant culture to solve challenges and opportunities.

Robust Safety Protocols and Compliance Systems

By understanding local regulations and striving to perform beyond compliance, companies uphold their social responsibility and safeguard operational continuity in Indonesia’s mining and metals sector.

Achieving long-term sustainable operations in Indonesia’s mining and metals sector requires a holistic approach that integrates risk management, operational excellence, and workforce empowerment. By embracing these strategies and cultivating a resilient organizational culture, companies can seize opportunities, navigate challenges, and thrive in Indonesia’s competitive landscape.

It’s crucial to adopt a forward-thinking perspective, focusing on sustainable growth and anticipating future trends.

Breaking down silos and fostering collaboration across departments ensures cohesive alignment and maximizes efficiency.

Begin with small, purposeful steps to generate immediate impact and momentum, paving the way for larger strategic initiatives

To maximize Indonesia’s potential in the mineral and metal sectors, an integrated strategy and approach is essential. This involves combining mining with downstream processing, adopting advanced technologies, and prioritizing ESG practices and proactive workforce development.

Strengthening operational risk management and operational efficiency, as well as implementing ESG practices ensure safety, sustainability, sustainable growth and regulatory compliance. Aligning exploration, mining, and refining drives growth, reduces emissions, and enhances Indonesia’s global market presence.

By showcasing responsible and sustainable mining practices, Indonesia can attract foreign investment and promote long-term industry growth.

The panelists