Enhancing Operational Safety with Process Safety Management

dss+ recently hosted an event at the World of Volvo Museum in Gothenburg. Among the topics discussed was Process Safety Management (PSM). During an insightful session led by Ari Palmroos, dss+ consultant, participants explored the challenges of managing operational risks to enable sustainable and resilient operations.

Through active dialogue and hands-on exercises, the session shed light on the challenges companies face in bridging the gap between awareness and action. Discussions emphasised the importance of equipping organisations with not just systems, but the skills and strategies needed to implement them effectively, ensuring safety and operational excellence remain central to their approach.

Bridging the safety gaps with PSM

In discussions surrounding resilient operations, Process Safety emerged as an essential component. At its core, Process Safety involves preventing unintended releases of chemicals, energy, or other hazardous materials during manufacturing processes, especially in high-risk industries. Effective Process Safety practices address risks like leaks, spills, equipment malfunctions, and over-pressures—conditions that can have severe consequences for both workers and the environment.

Despite significant efforts to establish management systems, ensuring their effective implementation remains a critical challenge for organisations. Key obstacles include insufficient senior leadership oversight, gaps in Process Safety competence, and limited understanding of major risk exposures at the operational level. Over-reliance on administrative controls, inadequate asset integrity programmes for ageing equipment, poor management of change processes, and the normalisation of deviations further erode safety resilience.

"Key obstacles include insufficient senior leadership oversight, gaps in Process Safety competence, and limited understanding of major risk exposures at the operational level."

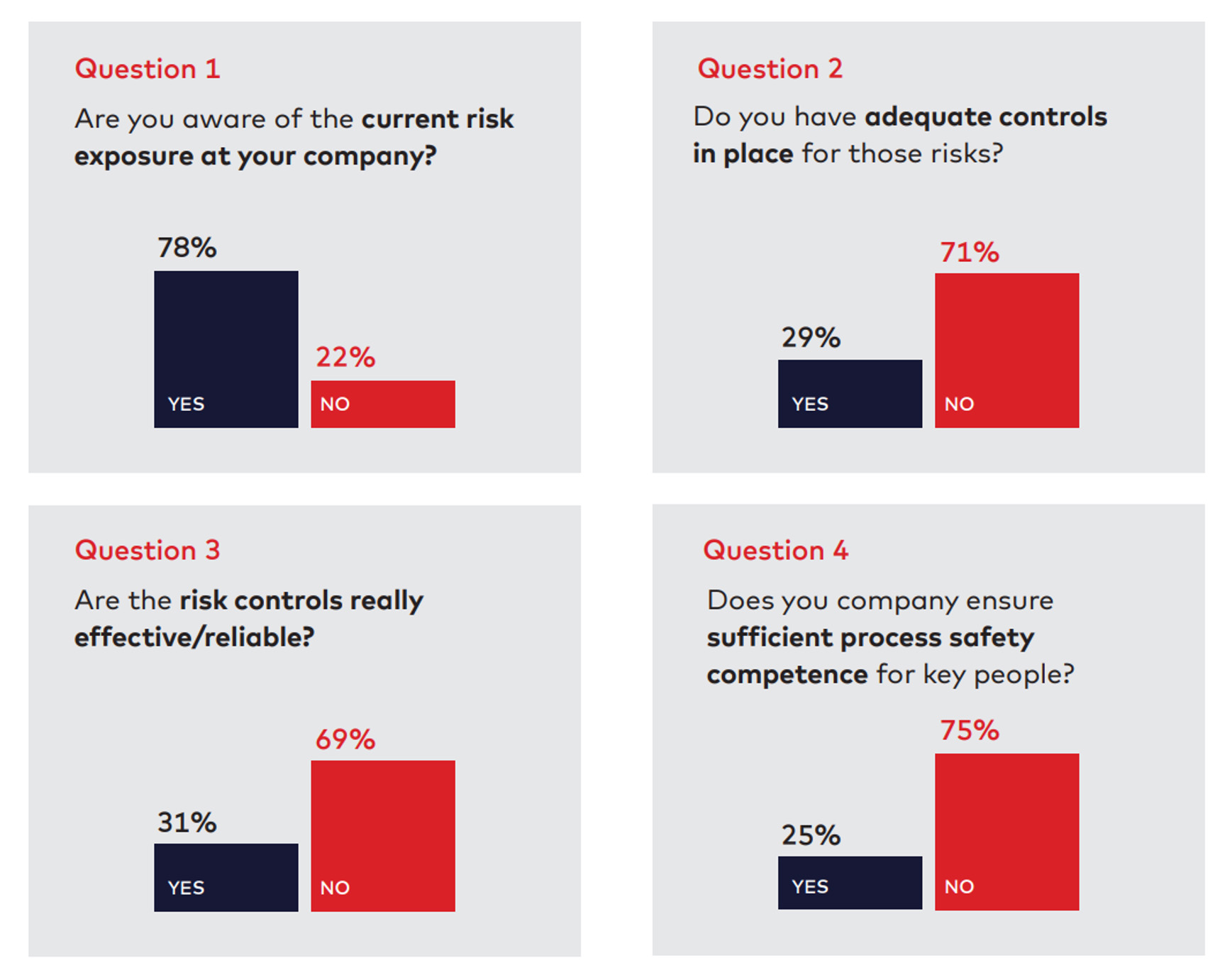

These challenges were underlined during a survey conducted in a session at the World of Volvo event. The survey, involving 12 companies representing 152,700 employees across six highrisk industries – Industrial and Manufacturing, Machinery and Industrial Equipment, Power & Utilities, Metals & Mining, and Oil & Gas—highlighted key areas for improvement in Process Safety Management (PSM). This exercise reaffirmed the critical importance of PSM in addressing operational hazards and ensuring the safety and reliability of industrial processes.

Notably:

- There is risk awareness but insufficient controls:

While 78% of participants reported being aware of their company’s risk exposure, 71% felt that adequate controls were not in place to address these risks effectively. - Lack of risk controls effectiveness:

When it came to the reliability of risk controls, 69% believed that the existing controls within their companies were neither effective nor reliable enough. - Competency in Process Safety Management:

Additionally, 75% admitted that their companies did not ensure sufficient PSM competence among key personnel, a gap that could weaken the organisation’s overall resilience.

"When it came to the reliability of risk controls, 69% believed that the existing controls within their companies were neither effective nor reliable enough.”

Embedding resilience in PSM:

Key pillars of a risk-based safety framework

To build resilient and effective Process Safety Management (PSM) systems, a risk-based approach is essential. This approach goes beyond basic compliance to create a system that identifies critical risk areas, tailors’ controls to specific hazards, and continually monitors effectiveness. Integrating risk evaluation directly into the PSM framework ensures that controls are not only in place but are adapted and resilient, addressing both current and emerging risks in operations. The core components of a risk-based approach include:

Management System Design & Implementation

It’s crucial to assess whether adequate governance is in place to provide a structured framework for managing risks with clear roles and responsibilities that put emphasis on accountability. An effective management system is key to driving continuous risk reduction.

Organisation & Capabilities:

Ensuring that the right skills and competencies are developed through an effective Learning & Development programme is essential to equip employees with the capabilities needed to manage and mitigate risks.

Leadership & Culture:

Finally, organisations must foster the right mindset, behaviours, and culture to support safety initiatives. Leadership needs to be committed to embedding safety into the company’s core values and operations.

"This approach goes beyond basic compliance to create a system that identifies critical risk areas, tailors’ controls to specific hazards, and continually monitors effectiveness.”

A comprehensive, risk-based approach that encompasses these areas can help organisations close the gap between risk awareness and effective risk management, ultimately building a more resilient and proactive safety culture.

For further insights on bridging safety gaps and embedding safety into organisational DNA, including strategies for leadership accountability and psychological safety, explore our related article on fostering safety cultures for long-term operational success.

How dss+ can add value

dss+ is a premier global sustainable operations management consultancy. Our goal is to help leading organisations Protect, Transform and Sustain what matters most – people, assets, communities, business performance, competitiveness, and sustainability – for future generations, at an organisational, national or global level.

We support safety and culture transformation by empowering companies to move beyond compliance, fostering proactive, resilient cultures that prioritise employee well-being. Through an integrated, risk-based approach, we help organisations systematically identify, assess, and mitigate risks, embedding a safety culture that strengthens both operations and resilience. We are proud of the impact we have made in driving our purpose to save lives and create a more sustainable future.

Author