Ahead of schedule: navigating planned Turnaround Execution for accelerated impact, reliable performance, and predictable financial outcomes

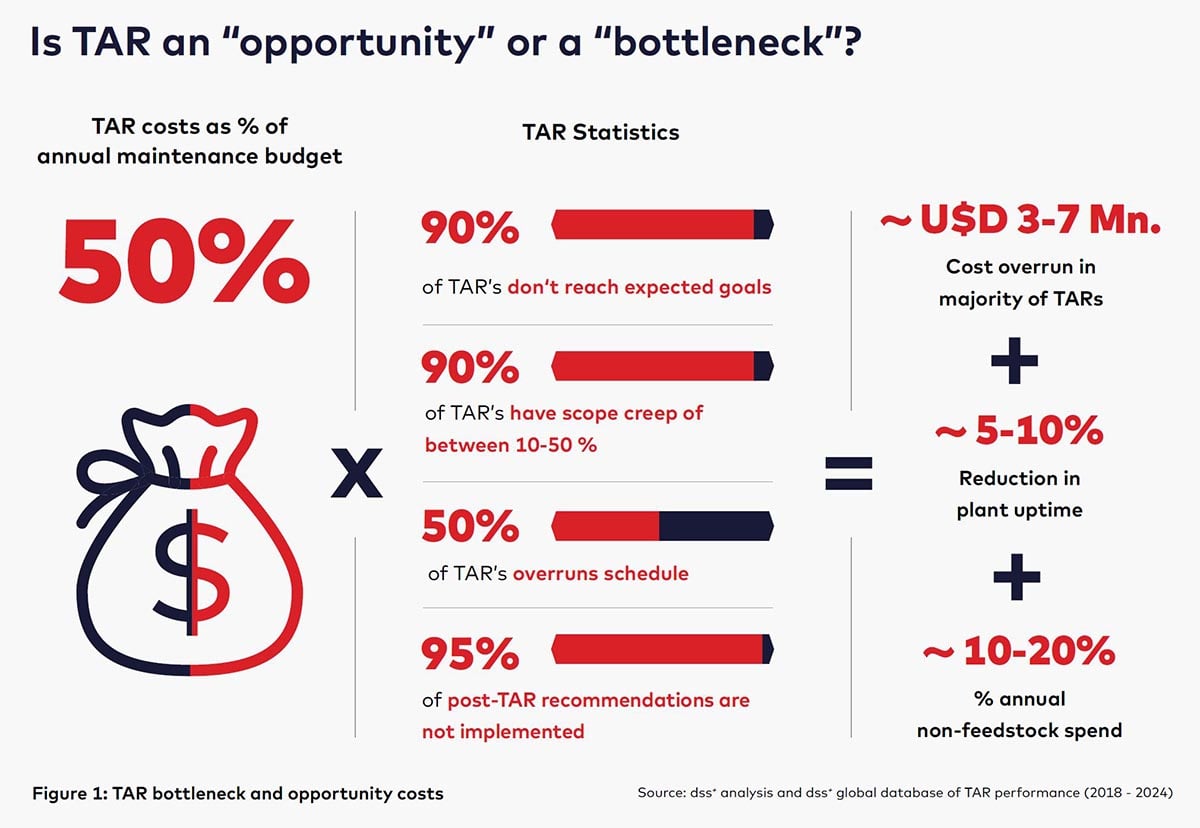

Turnarounds (TARs), often seen as a "necessary evil" in the energy and resources industry, are costly, time-consuming, and complex. Despite these challenges, TARs are essential for maintaining compliance, enhancing safety, improving environmental performance, and ensuring plants operate efficiently. Successful TARs enable reliable and sustainable operational performance, but they are often perceived as bottlenecks to achieving financial, production, and safety goals. However, if viewed through a new lens, could TARs also be considered an opportunity to realise value?

Turnarounds represent a substantial financial investment for energy companies across the upstream and downstream value chain. Executing these projects incurs high costs and downtime during the turnaround directly impacts the organisation’s revenue. Despite the high stakes, TARs often face challenges and may fall short of meeting benchmarks, particularly regarding time overruns.

In addition to financial considerations, various factors contribute to the potential costliness of TARs. From a human resources perspective, TARs require a significant allocation of internal resources for planning and supervision, diverting them from their usual responsibilities. Furthermore, an additional complexity comes from the large volume of contractors needed to be onboarded and managed effectively to ensure safe and efficient simultaneous operations.

Root causes for poor performance in Turnarounds

As illustrated above, TARs present significant opportunities for improvement in their execution despite being high-stakes events with the potential to greatly impact an organisation. By examining performance factors relevant to their business, organisations can identify and address the root causes of performance issues.

Quick and focused efforts from a multi-disciplinary team can effectively address several of them.

Based on our experience, the top four root causes are identified as follows:

Poor governance

One of the most crucial facets of a successful TAR execution is managing the flow of information, including defining the right Key Performance Indicators (KPIs) that serve as a ‘single source of truth’ and provide visibility of the ‘field reality’ to support enhanced decision making. TAR overruns are often caused by a lack of prompt identification and resolution of bottlenecks and issues, as well as inadequate coordination among diverse teams. Ensuring the availability of all relevant stakeholders and obtaining transparent updates on their activities during a turnaround can be a challenge.

Absence of operational discipline

TAR planning milestones are often not met due to a prevailing mindset of “catching up later.” However, as these milestones are missed, their cumulative effect typically results in incomplete tasks, forcing execution teams to work against unachievable targets.

Inadequate contractor management

Turnarounds are labour-intensive events, typically involving thousands of contractor resources and millions of work hours compressed over a period of 20-40 days. A key consideration that is consistently overlooked in turnarounds is the efficiency and

productivity of the contractor resources.

Lack of skills

A lack of training and development can push organisations into a capability trap, limiting their knowledge of best practices and methods. Many organisations fail to continuously train and develop employees in the turnaround team.

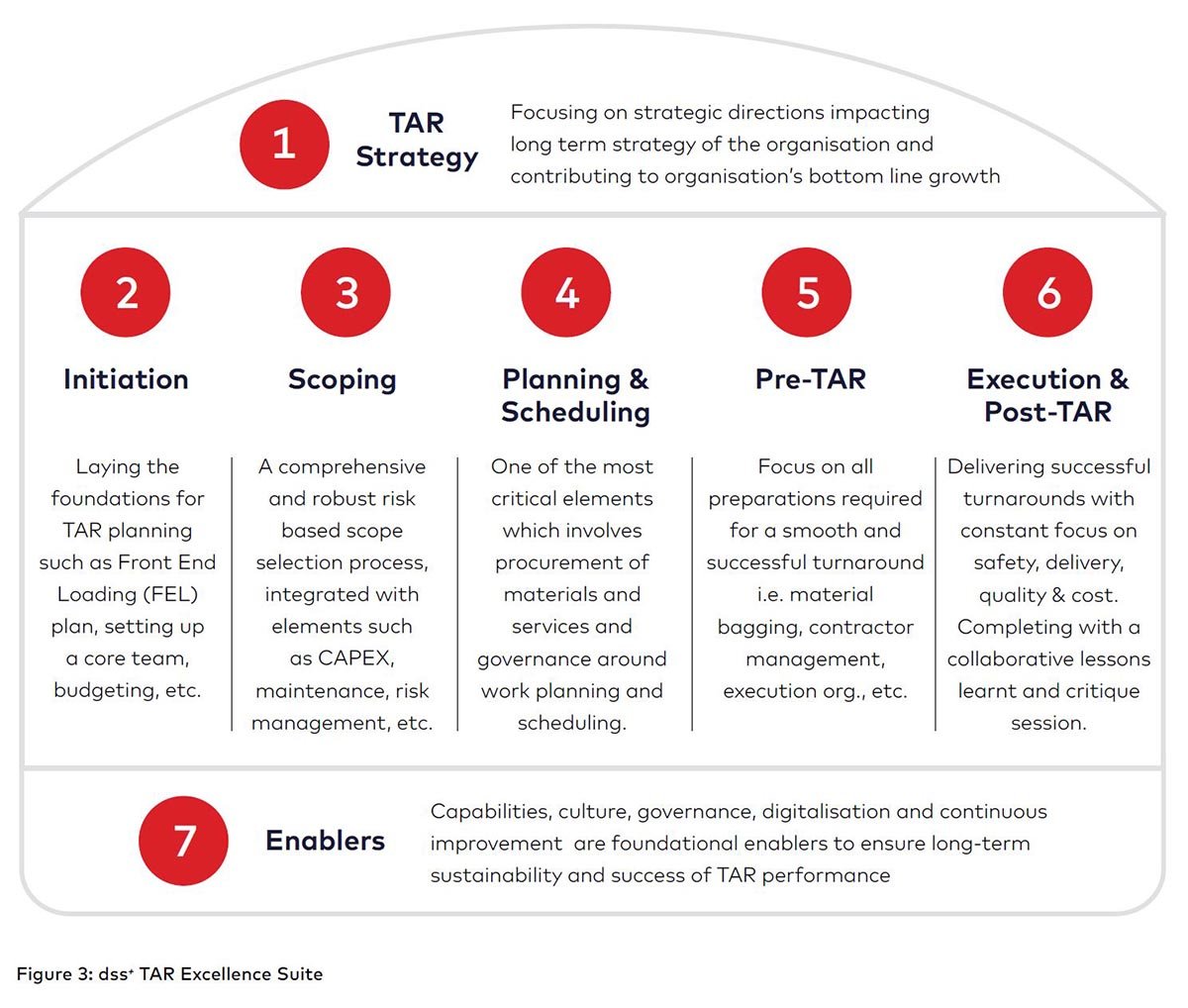

A framework for efficiency and value release in TARs

Taking a comprehensive approach to TARs, supported by a framework encompassing all essential processes and improvement levers, is crucial for success. The TAR Excellence Framework, designed by dss+, provides various best practice tools, methodologies, templates, and processes meticulously crafted for seamless deployment in upcoming turnarounds.

Despite the critical importance of efficient and well-planned TAR execution, many energy companies are primarily focused on the day-to-day operations of their plants. Consequently, they may lack the necessary in-house capabilities or bandwidth to execute a thoroughly planned turnaround independently. Recognising the factors that can contribute to poor TAR performance—such as poor governance, absence of operational discipline, inadequate

contractor management, and lack of internal skills—partnering with an expert advisor in TAR management may offer valuable support in ensuring that TAR adds both financial and non-financial value to the organisation.

Selecting an expert partner for an energy turnaround

At dss+ we believe in walking the path to Turnaround excellence alongside our clients, shoulder to shoulder. Our approach is straightforward: we meet our clients where they are and journey together towards resilient and sustainable performance.

We help build capability to empower companies to tackle turnarounds with confidence. By leveraging our expertise, resources, and integrated approach, we assist our clients in overcoming challenges, optimising business performance and fostering sustainable growth.

Here is how dss+ can help:

- Identify deviations or best practices, highlight bottlenecks and assess the financial impact of delays.

- Collaborate closely with the organisation, leading by example, facilitating skill exchange, and assisting in realising financial benefits.

- Establish the fundamentals of a successful TAR and provide support to planning teams throughout the planning and execution phases.

- Enhance and embed critical TAR management skills for in-house excellence.

- Overhaul existing TAR processes and align with industry best practices.

- Facilitate “challenging discussions” to ensure an efficient turnaround.

Conclusion: Staying ahead of the curve

Turnarounds (TARs) play a pivotal role in energy asset-intensive resource industries. However, despite their profound impact across executive levels and financial and operational performance, TARs often receive inadequate attention within organisations, lacking awareness of best practices.

This oversight is compounded by the substantial costs associated with TARs, encompassing both the loss of regular production and overall expenditure, alongside significant safety risks. Poorly executed TARs can disrupt ongoing operations and even

compromise subsequent TARs, further exacerbating costs within an already challenging operational landscape.

However, organisations can mitigate these challenges by adopting a systematic approach to TAR improvement. This approach involves shifting from a reactive to a proactive approach to meticulously defining scopes, planning and optimising schedules, establishing robust governance structures, and enforcing stringent operational discipline. Additionally, fostering enhanced stakeholder collaboration and elevating technical proficiency are critical components of this strategy.

Implementing these improvement levers has demonstrated the potential to yield significant cost reductions, sometimes up to 20%.* For medium to large organisations, such savings could translate into multimillion-dollar benefits annually.

Moreover, beyond cost-saving endeavours, substantial potential exists to enhance plant reliability and production through improved TAR execution quality. Partnering with adept experts who foster collaboration across all stakeholders, address root causes comprehensively, and uphold operational discipline rigorously can further mitigate TAR costs. In doing so, organisations unlock value by cultivating safer, more efficient, and reliable operational frameworks.

*Source: dss+ library of frameworks